Nov 2018 Meeting

The November meeting of the CraobhEo 2018/19 year took place on the 8th November in the CraobhEo Centre in Aghamore.

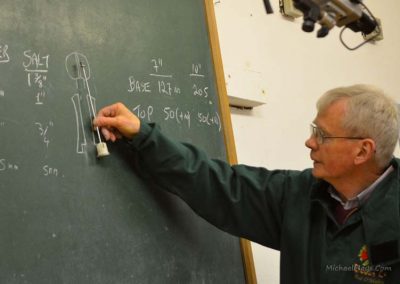

Pat O’Malley who was our demonstrator for the evening.

Pat’s project for his demo was a salt and pepper set. On a show of hands in the room not many had attempted to do this before which is surprising given the popularity of these items. Starting off with the proper dimensions for the given set makes things more straightforward.

Both the salt and the pepper units look the same on the outside but the hardware and the internal bore are different. Each shaker consists of a head and body (both the same length). The size of the head in relation to the body is a design decision but the overall length of both together remains the same which is determined by the hardware (6″, 7″, 10″ or 12″).

Guidelines as follows;

7″ Set 10″ set

Head Height 50 50 (add 10 mm to both for insert into body)

Body Height 127 205

Salt Pepper

Base of Body recess width for hardware 1 3/8″ 1 1/2″

Body recess width for salt or pepper 1″ 1 1/8″

Recess width in Head 3/4″ 3/4″

The first step is to turn blanks to a cylinder for the head and body and dimension both to side as above. Diameter for head can be approx 55 mm and body 65 – 70 mm. For the demo the body had been laminated from walnut with maple veneers. The head was maple. Mount the body and drill out recess at base for hardware to a depth of 12 mm (pepper) or 8 mm (salt). Next drill the centre halfway then remount and drill the other half. Mount the head and drill a recess to a depth of 10 mm. Drill a further hole 5 mm diam through the rest.

Next remount the head and turn a spigot 10 mm wide to fit into the body. The shaker will twist around this. At this point the hardware should be inserted through the body and head and checked for fit. Readjust as necessary but bear in mind both shakers must look the same from the outside.

Finally turn the outside of the shaker. Remount the body and turn outside to a shape of your choice. Then mount the head and turn to a sphere shape making sure the bottom of the head matches in with the collar of the body.

Feedback was given to the chapter on the judges comments for the ferris wheel chapter challenge. A frame is currently being made so it can be placed at different venues around the county to raise money for our chosen charity this year, Downs Syndrome Mayo. Next year’s project will be a crane so ideas and participants are welcome at this point. The Christmas Party was discussed, more later on prices and venue.

Competition

The November competition was for a pedestal bowl. Well done to all who took part and thank you for submitting your piece.

Competition piece for December is a natural edge piece.

Monthly Chapter Competition Winners

Winner – Dickie Barrett

Second (Joint) – Michael Lackin

Liam Horan

Paddy Treacy

Third – Tom Burke

CraobhEo Nov 2018 Meeting

Competition Winners; (L-R), Martin Grogan (Joint 2nd), Liam Horan (Joint 2nd), Paddy Treacy (Joint 2nd), Dickie Barrett (Winner), Padraig Grealis (3rd)