Craobh Eo members visited Liam O’Neill’s Studio in Spiddal on Sat 10 June 2017 for a 1 day workshop. This was a nice way to round off the woodturning year.

Liam started the day with a outdoor sculpturing demo. These pieces can be very large so a different approach is needed to normal woodturning. To this end a bespoke lathe has been built to accommodate the redwood sculptures. This can be rotated by hand and a hoist mechanism is also available for support. A chainsaw mounted on a pivot is used to remove the wood. Most of these sculptures are commissions.

We then moved inside for a bowl demo. This consisted of first roughing out a wet cherry blank and then finishing a dried out blank. A 10% wall thickness is left during roughing. The blank is then dried out in a home built kiln. This demo also gave him an opportunity to give us the history of his Irish Grind and explain how it is used to remove wood quickly. Techniques are explained are he goes along. Sheer scraping is used for final finishing on the outside and scrapers are used to achieve final finish inside the bowl.

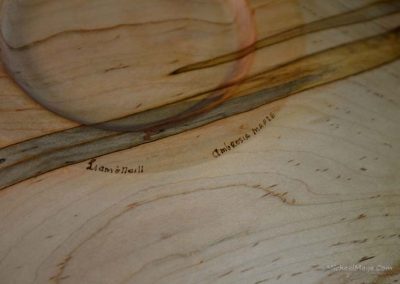

Next up was the spalted cherry box with purple heart rim. A wet blank was shaped and then parted to give a lid and base blank. Both are hollowed out. The lid, purple heart rim and base are then laminated and left to dry over time. A dried out blank was then mounted on the lathe. The lid end was shaped first on the outside before being parted off from the body. The lid was mounted and hollowed out before cutting a recess to fit the body into. Next the body was mounted and hollowed out. Note hollowing of both before fitting lid. Fitting of the lid is a careful process starting from the outside and working inwards. Parfix 3402 is coated onto the spalted wood to give it strength. When dry final cuts are made using a round scraper on the inside. The box is finished with EEE and ShellaWax which gives a lovely finish. See photos below.

The final demo was finishing a large platter. Any holes can be filled with a mixture of epoxy resin and hardener (tablespoon to teaspoon). Also copper powder fillings can be used to fill small holes. Work on the outside and turn a nice ogee shape. Round corners and edges.The inside starts at the rim with grooves using a special tool. See photo. Undercut the rim using a spindle gouge and shape inwards towards the centre. Turn gouge on its side for final cuts. Finish with a scraper. After sanding apply three coats of Ronseal SatinCoat. Finish with steel wool dipped in liquid paraffin. All finishes nowadays are food safe one properly dried out.

This was a great workshop where many topics were covered by Liam. Everyday problems were encountered and approaches to solving them discussed and applied. Techniques were discussed as we went along, use of the proper tools for the job and especially sharpening. Design was covered as this can be the biggest challenge.

Great support from Christy during the day who was always on hand. Thanks to Kathy was refreshments morning and afternoon. Lastly a big thank you to Liam for making this such a successful day.

We really enjoyed our day in Spiddal, a beautiful party of the world.