Apr 2017 Meeting

The April meeting of the 2016/2017 year was held on Thurs. 13th April in the Craobh Eo Centre (Old Schoolhouse) in Aghamore.

Mr. Harry Emerson was our special guest for the evening from the Cross-Border chapter.

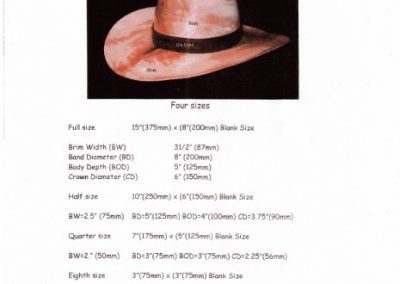

Harry who is renowned for turning hats gave a brief introduction on hat making describing sycamore as the best wood to use. Harry on this occasion used a piece of Ash with a moisture content of approx. 40%. The piece was shaped into a semi dome with the chainsaw before it was mounted on the lathe with a 4 “chuck.

Harry proceeded to true up the top and sides and a spigot was turned on the crown of the hat for the 4“chuck. Next a recess was made with the parting tool out 65mm from the centre of the crown to a depth of approx. 40 mm and then working in from the side of the body of the hat a large ring was removed which Harry explained could be used for picture frames. Again, working in from the crown end of the hat another recess was formed again to a depth of 40mm and then working in from the side of the body another ring was removed. As this is forming the body of the hat, Harry ensured that it was tapered outwards as he worked towards the brim of the hat. When Harry was happy with the general shape of the hat he started to refine the crown and body of the hat leaving a rim which was decorated using art pencils called intense ink. As the lathe was turning Harry moved the pencil back and forth along the rim to get the required decoration.

The piece was then reversed mounting it on the spigot that was formed on the crown. Harry trued up the underneath side of the brim by pushing the gouge in towards the centre.

Harry slowly brought down the brim to a depth of 4.5mm checking to ensure the brim was the same depth on the outside as at the base of the body. As he pared down the brim he supported the brim by placing his finger at the back to support and measure the heat of the brim.

Next a hole was bored into the body of the hat to the depth he was going to hollow the inside of the body of the hat. Then setting the toolrest just below centre Harry started to hollow the body of the hat constantly checking the width of the body to ensure it maintained the same width of 4.5mm as the brim. Harry sprayed water on the hat and meticulously worked at getting the crown the same width as the body and brim. Then using a round nose scraper held at an angle of 10 degrees the inside of the body was cleaned up. When satisfied Harry mounted a homemade piece with a light inserted. The hat was then placed over the piece and the tailstock was used to hold it in place and centre it correctly. The spigot on the crown was then reduced sawing off the last remaining piece and chiselling it to a very fine finish. During the demo, Harry constantly used the shavings to prevent water landing on the lathe and in removing the spigot used the light to assist him in knowing when he was close to the required depth.

Harry then placed the hat on a frame he had made up using elastic bands to clamp the hat in place reminding us of the importance to keep wetting it daily.

This was a thoroughly enjoyable demo by Harry, ably assisted by Minnie who ensured he was on his toes always not only for the turning of the hat but also the little nuggets of info picked up during the evening.

We also welcomed two members of the Men’s Shed to our meeing.

April's Competition

April’s competition was a hand me around bowl. Nice bowls on show. Thanks to all you submitted a piece.

May’s competition will be an inside outside piece.

Result for April.

Winner Tom Jordan

Second Richie Barrett

Third Liam Horan