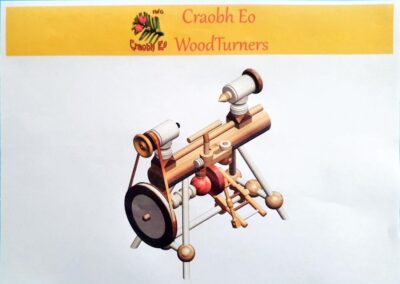

Irish Woodturning Guild 2023 Chapter Challenge.

CraobhEo Lathe Entry

The IWG Chapter Challenge is generally well supported in CraobhEo and the 2023 Lathe project was no exception. Members were eager to get involved once we got going and put some ideas on the table. In previous years we have been able to use it as a charity fundraising vehicle which strikes a chord with everyone.

Introduction

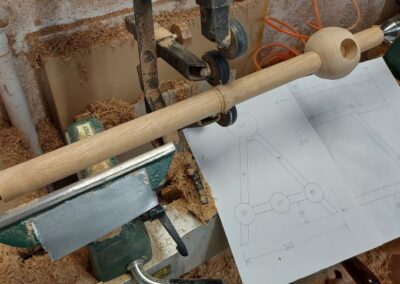

It’s always nice to work with colleagues and introduce new skills and techniques to our repertoire. We assembled a team of nineteen CraobhEo members all eager to get turning. Richard Barrett produced drawings with dimensions of the various parts of the lathe, a great start. Members liaised with each other to ensure the pieces they were making matched up with each other so final assembly became a little easier. We had regular meetings to manage the project and set up a WhatsApp group to keep each other informed. A lot of planning and work was undertaken by members to get the project over the line.

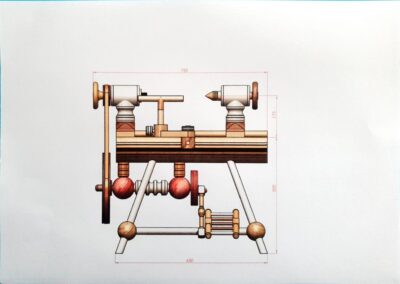

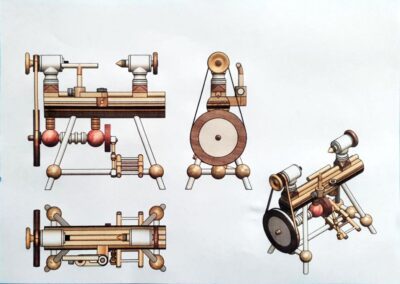

The lathe chosen for our project did not correspond to any particular manufacturer’s model, it could be referred to as a universal model. It is comprised of a lathe bed on legs, headstock, tailstock and treadle. There were other items such as a chuck, steady, Longworth chuck and various chisels and other useful items. The project was divided into a number of sub projects for members to take away and work together on in groups.

Bed of Lathe

CraobhEo member – Willie Creighton

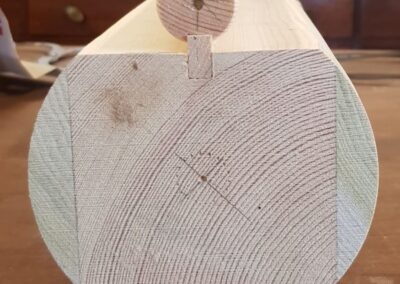

Willie took on the job of making the bed of the lathe. He laminated the block for the lathe out of oak, walnut, elm and birch ply. The base was turned round with a flat on top. Then he turned an oak round rail, 30 mm diameter and attached this to the top of the bed with a 4mm cherry tongue. This would allow the headstock, tailstock and the steady to attach and slide along the bed of the lathe.

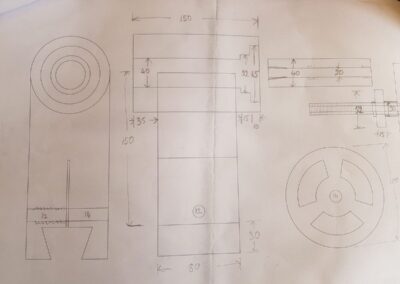

Headstock

CraobhEo members – Tom Jordan, Kevin Leonard

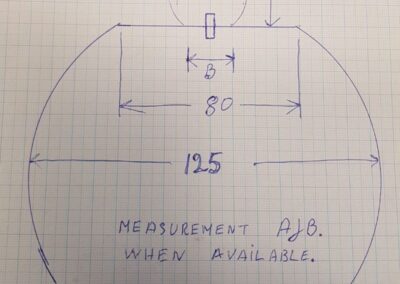

“My part of the Chapter Challenge began with the headstock. Starting with a 100 mm ash block, I cut an 80 mm hole in the side to take the pedestal. Next I drilled the core of the block to take the threaded shaft, then assembled the unit.” Tom Jordan

The challenge here was to turn the spindle, thread 1 inch by 6 tpi.

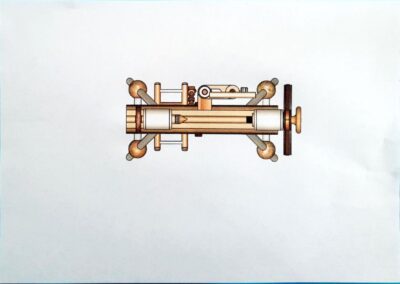

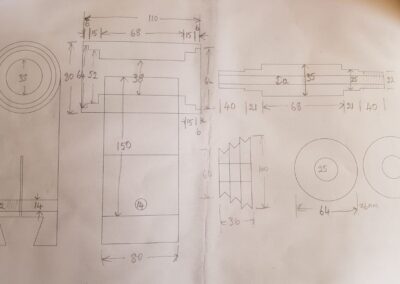

The Tailstock

CraobhEo member – David Knox

The tailstock is made up of a number of parts. The base which slides along the bed of the lathe and the tailstock housing including the neck that sits on the base. The cylinder moves in and out. At the outer end is the wheel that turns the spindle inside the housing and the tailstock centre is on the other. There is knockout bar to eject the centre and a locking screw to lock the cylinder in place.

The Stand

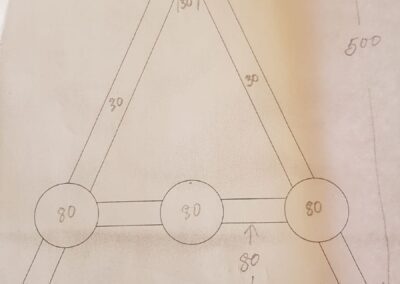

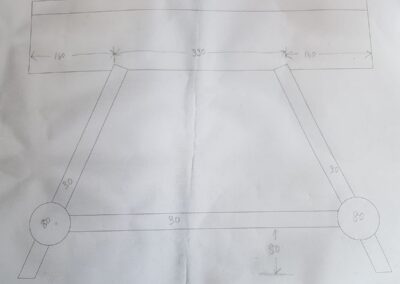

CraobhEo members – Michael Maye, Martin Wilson, P J Hallinan

The stand is made up of four ash legs, 30 mm diameter, splayed at a compound angle and two end spindles which are connected with a stretcher rail. At each intersection there is an oak sphere, 80mm diameter, to connect the rails and legs together. The top of the legs are attached to the bed of the lathe.

The Treadle, Banjo

CraobhEo members – Richard Barrett, Padraig Grealis

The treadle was made by Richard Barrett ably assisted by Padraig Grealis. There are a number of moving parts to the treadle so individual items had to be carefully turned and fitted for it to work. They also made the banjo. The treadle attaches to the underside of the lathe and when operated manually it will turn the headstock spindle. A large segmented 300 mm wheel is attached to the headstock end of the treadle and a smaller 110 mm wheel is attached to headstock spindle directly above. A leather belt connects these two wheels. There is also a 50 mm handwheel on the headstock spindle for starting the treadle. The tailstock end of the treadle has another wheel with the treadle pedal attached. When the treadle pedal is operated, it turns the headstock spindle. The banjo is attached to the lathe bed and can swivel in any direction to facilitate the tool rest.

The Steady

CraobhEo member – Pat O’Malley

The Steady slides along the bar of the bed and can be held in place by two locking nuts. Materials used are maple and walnut. The main ring was made from three segmented rings, glued together. The arms made of maple have slots to allow them to be moved in and out. Bolts were made to lock the arms in place. Walnut rotating wheels hold the piece being turned in place. The Crown threading chisel was used for the male thread and an M10 tap for the female thread.

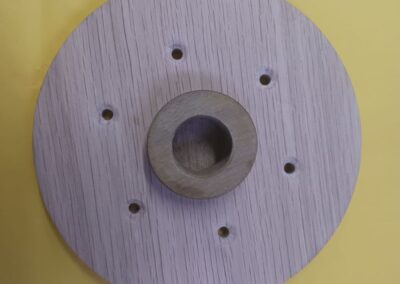

The Longworth Chuck

CraobhEo member – Patrick Munnelly

The Longworth chuck attaches to the headstock spindle via a threaded female insert in the centre boss. The wood for the revolving disks needed to be stable and relatively thin in diameter. Eight slots were cut in each disk to recreate the famous Longworth design. The disks rotate on the centre boss axle. Eight locking studs with wooden turns lock the disks in place to hold an item.

Chuck

CraobhEo members – Ian McDougall

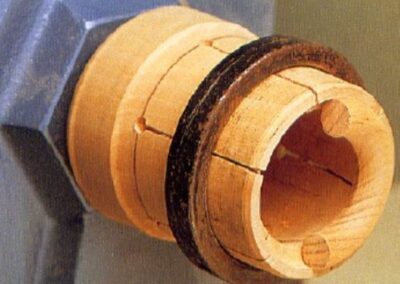

Ian took on the job of making the chuck. This is a compression chuck. He has documented the process that he went through below.

Making the Chuck

To make this chuck, first I turned a cylinder between centres, then I turned a taper on the cylinder in the centre section. I then mounted the cylinder in the chuck jaws and bored out the centre section to a parallel cross section which made the bottom of the hole to be a thin section to allow the jaws that would be produced later to flex when the locking ring was pushed to the top of chuck body. I turned a dovetail on the inside of the open section to be able to grip a work piece. While the chuck body was on the lathe I marked the rim for the slots to be cut next on the router table. I made a jig to hold the chuck body on the router table and cut the slots in the body. I then turned the boss for the chuck mounting and threaded the boss and parted off the section I needed. I turned a mandrel to mount the chuck body to and turned a recess for the boss and glued that in. I made some veneers for the locking ring and glued up a laminated ply piece then mounted it on the lathe and cut the locking ring. I had to compress the jaws to fit the ring over the chuck body. I then repeated all the operations to make a second chuck but smaller size. Ian McDougall

Turning Tools

CraobhEo member – Louise Wilde

“The tools are based on a Robert Sorby design and are 7/8 scale. Handles are turned from ash with a walnut inlay. The shafts are mahogany with the exception of the roughing gouge which is beech. All spindle turned with the exception of the roughing gouge which was off centre turned. A small amount of hand carving was also done on some of the gouges due to the shortness of my drill bits.” Louise Wilde

Tools

CraobhEo members – Paddy Farrell, Liam Horan, Sean Morley, Declan O’Boyle, Denis O’Donnell, Andrew Reeve

Andrew made the tool turntable

Declan made the faceplate.

Denis made the mallet and centre finder.

Liam made a compass and tool holders.

Sean made the callipers

Paddy turned the bradawl.

Finishing

CraobhEo member – Ian McDougall

Ian took on the most important job of all taking the sanded pieces and finishing them to his own high standard. Members had to avoid glue lines on bare wood. Several coats of sanding sealer and lacquer was applied until the satisfactory end result was achieved.

Assembly

CraobhEo members – Willie Creighton, Tom Jordan

Finally the job of assembling and making it all come together was undertaken by Willie and Tom. A significant task always and this was no exception. Many hours were devoted to getting it all over the line. The first part of the assembly was putting together the legs and attaching them to the base. A vital part of their brief throughout the project was ensuring everything was fitting together as the project progressed. The headstock, tailstock and steady that used the rail had to be running smoothly. Spindles had to fit into chuck and Longworth chucks. Last of all there was the treadle to assemble and get working with help from Richard who masterminded the treadle.

Booklet and Social Media

CraobhEo members – Michael Maye, Pat O’Malley

We setup a WhatsApp group to keep people informed and allow information to be shared. Members were encouraged to take photos of their work as they went along. This publication only shows some of those photos, lots more can be seen on the CraobhEo website.

Participants

CraobhEo members

|

Richard Barrett Willie Creighton Paddy Farrel Padraig Grealis P.J. Hallinan Liam Horan Tom Jordan David Knox Kevin Leonard Michael Maye |

Ian McDougall Sean Morley Declan O’Boyle Denis O’Donnell Pat O’Malley Patrick Munnelly Andrew Reeve Louise Wilde Martin Wilson |

List of Materials

|

2 Pieces Irish Oak 660 x 130 x 25 mm 2 Pieces Walnut 660 x 130 x 12 mm 2 Pieces Elm 660 x 130 x 12 mm 1 Piece Birch Ply 660 x 130 x 15 mm 2 Pieces Birch Ply 660 x 130 x 3 mm 1 Piece Oak 660 x 35 x 35 mm 1 Piece Cherry 660 x 15 x 6 mm 4 Legs Ash 490 x 35 x 35 mm 2 Cross Rails Ash 230 x 35 x 35 mm 4 Stretchers Ash 530 x 35 x 35 mm 1 Piece Irish Oak 500 x 95 x 95 mm 1 Piece Yew 250 x 100 x 100 mm 4 Piece Ash 400 x 100 x 100 mm 2 Pieces Walnut 80 x 80 x 20 mm 2 Pieces Mahogany 180 x 80 x 20 mm 2 Pieces Ash 80 x 80 x 22 mm 1 Piece Mahogany 80 x 80 x 6 mm 1 Piece Oak 80 x 80 x 6 mm 1 Piece Poplar 80 x 80 x 22 mm 1 Piece Birch Ply 80 x 80 x 2 mm 1 Piece Beech 450 x 45 x 45 mm

|

1 Piece Greenheart 300 x 30 x 30 mm 1 Piece Red Deal 450 x 70 x 70 mm 1 Piece Mahogany 60 x 60 x 60 mm 1 Piece Boxwood 50 x 50 x 40 mm 1 Piece Mahogany 80 x 80 x 6 mm 1 Piece Yew 50 x 45 x 45 mm 1 Piece Mahogany 80 x 80 x 6 mm 1 Piece Maple 170 x 22 x 22 mm 1 Piece Boxwood 320 x 16 x 16 mm 1 Piece Ply 400 x 200 x 200 mm 1 Piece Walnut 220 x 110 x 30 mm 1 Piece Maple 110 x 110 x 12 mm 1 Piece Walnut 900 x 35 x 8 mm 1 Piece Maple 900 x 35 x 8 mm 1 Piece Maple 170 x 25 x 10 mm 1 Piece Walnut 100 x 35 x 20 mm 1 Piece Maple 80 x 10 x 10 mm 1 Piece Holly 200 x 35 x 35 mm 1 Piece Ash 1500 x 75 x 10 mm 1 Piece Mahogany 1200 x 75 x 10 mm 1 Piece Sp. Beech 225 x 225 x 32 mm

|